August 2025 – In conversation with ARC Clean Technology

When the Canadian Nuclear Safety Commission (CNSC) completed Phase 2 of its Vendor Design Review (VDR) in July 2025, for ARC Clean Technology’s advanced small modular reactor, it marked a major step forward for a project that could help shape New Brunswick’s clean energy future.

To learn what this means and why it matters, Atlantica spoke with Bob Braun, Senior Vice President and Chief Operating Officer of ARC Clean Technology Canada, in August 2025. With more than 40 years in the nuclear industry, Braun has managed some of North America’s largest nuclear facilities. Today, he’s leading ARC’s Canadian operations, spanning from the Point Lepreau site to potential industrial hubs like the Port of Belledune.

Bob, can you tell us about your background and how you came to join ARC?

I’ve been in the nuclear business for 43 years, most of it in the U.S. commercial nuclear sector. I started as a licensed Senior Reactor Operator at the Limerick Generating Station and went on to management roles, including Plant Manager, Vice President of Nuclear Oversight at Exelon, and Site Vice President at multiple stations. I later became Chief Operating Officer and Chief Nuclear Officer for Public Service Enterprise Group. I retired eight years ago, but wasn’t ready to stop working

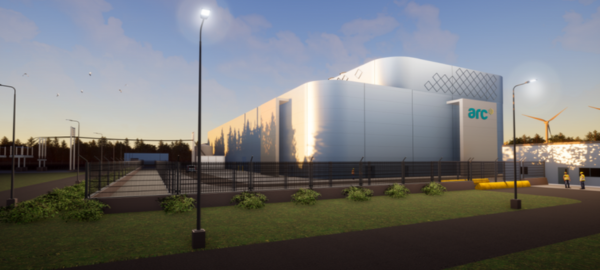

ARC was founded in 2006 to commercialize a U.S.-developed sodium-cooled, metal-fuelled fast reactor, the technology behind the Experimental Breeder Reactor-II (EBR-II). Our founders wanted to ensure that this proven design, funded by the U.S. government, didn’t disappear. In 2016, ARC was incorporated in Canada to take advantage of the CNSC’s technology-neutral, risk-informed regulatory framework. Soon after, NB Power selected ARC and Moltex for future development at Point Lepreau [Nuclear Generating Station]. Our parent company in the US is also a recipient of the U.S. Department of Energy’s Advanced Reactor Demonstration Project Award, a $35 million grant, and has been carrying out related design activities in the United States. While ARC works in both countries, the primary focus is Canada, where Point Lepreau represents the best near-term commercial opportunity.

Bob Braun

Senior VP and Chief Operating Officer - ARC Clean Technology

For someone hearing about it for the first time, what is the ARC-100?

The ARC-100 is a 100 megawatt (MW) advanced small modular reactor. It’s cooled by liquid sodium, uses metal fuel, and operates at atmospheric pressure, which means a simpler, inherently safe design.

“One ARC-100 could power about 75,000 homes.”

It’s flexible too. The ARC-100 can produce both electricity and high-temperature heat (500°C sodium or superheated steam), making it attractive to industrial customers. It can also generate valuable medical isotopes. Another benefit of our reactor is that it has a 20-year refuelling cycle, which lowers operating costs and reduces waste volume.

How is it different from conventional water-cooled reactors or the CANDU reactor at Point Lepreau (Nuclear Generating Station)?

The CANDU reactor at Point Lepreau is a 660 MW Generation 2 unit that uses natural uranium and heavy water coolant, operating at high pressure. The ARC-100 is a proposed Generation 4 reactor. It is designed to be smaller and simpler, using liquid sodium coolant and metal fuel. Its design incorporates advanced, inherently safe features intended to reduce the need for complex safety systems while still meeting, and potentially exceeding, the safety standards of earlier generations. That makes it cost-competitive, even at a smaller size.

Conventional reactors, like Canada’s CANDU units, operate under high pressure to keep water from boiling at high temperatures, similar to a pressure cooker. While still very safe, these designs require large, complex containment systems and multiple safety systems. The ARC-100 operates at atmospheric pressure, eliminating highly energetic accident scenarios. Sodium boils at about 900°C; we operate at 500°C, with a 400°C margin. Even in a worst-case accident, we’d stay 200°C below boiling. This allows for a simpler, less costly design while maintaining inherent safety.

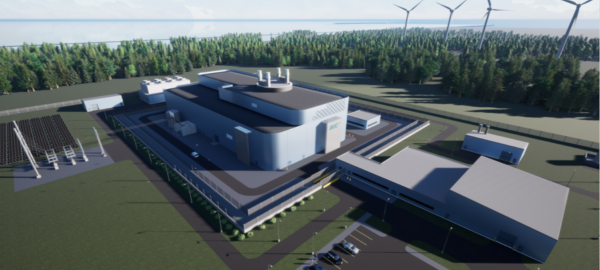

“Physically, the ARC-100’s footprint is small. The entire plant and safety perimeter would fit on the footprint of the Saint John Costco and its parking lot, with the plant structures about half the size of the store.”

Can ARC-100 work alongside renewable energy sources?

Yes. The same physics that make it inherently safe also make it ideal for load-following — adjusting output to match demand when wind or solar output changes. It also provides grid stability and voltage support, which renewables can’t always do on their own. The ability of advanced SMRs like the ARC-100 to provide clean, reliable, and load-following generation capacity will strengthen electricity grids with increasing amounts of renewable energy sources in their generation mix.

ARC just completed Phase 2 of the CNSC’s Vendor Design Review. What does that mean for the project?

It’s a rigorous process with 19 technical focus areas, and we started it in March 2022. Finishing Phase 2 means one of the most credible regulators in the world has found no fundamental barriers to licensing our reactor. I believe this announcement has significantly reduced the project’s development risk and has boosted investor interest.

What’s the timeline from here?

NB Power has already submitted its Licence to Prepare Site application. Our next step is to complete the design and safety analysis needed for a Licence to Construct application by 2027. If all goes as planned, the first ARC-100 at Point Lepreau could be in service in the early 2030s.

Can you discuss the opportunities for ARC with the Port of Belledune? What could happen there?

The Port of Belledune aims to create a Green Energy Hub with year-round port access and strong market links. We’re exploring the potential to site multiple ARC-100 units there to serve industries such as clean steel, ammonia production, and possibly AI data centres. The site could host up to 1 GW of demand.

Our goal is to build a fleet of reactors. In addition to the first commercial demonstration unit at Lepreau and ARC-100 units in Belledune, we can also satisfy NB Power’s plan for an additional 600 MW of SMR capacity, replacing existing fossil fuel plants. And we plan to replicate that fleet deployment strategy in other provinces and countries. Fleet deployment brings economies of scale through shared training, engineering, and procurement.

What does this mean for local jobs and businesses?

In the near term, most work will be in engineering and design. Once construction starts, there will be big opportunities in civil works, trades, and nuclear-qualified labour.

Our plan is to build a fleet, moving skilled workers from one project to the next to create steady, long-term employment.

Another industry that we see local potential for is the production of life-saving medical isotopes. The ARC-100 is a fast reactor. This makes it suitable to produce very high quantities of medical isotopes, which would require a local ecosystem and supply chain to support production and distribution.

How is ARC working with communities and Indigenous partners?

We’ve received tremendous support from Indigenous communities, especially through the North Shore Mi’kmaq Tribal Council. They’ve been strong advocates and valuable partners in discussions about clean energy development.

In general, we make it a priority to be present in local outreach activities, often alongside NB Power, so people can speak to us face-to-face. Those conversations build trust, answer questions directly, and often turn curiosity into support. We’re also committed to ensuring that the economic benefits of these projects are shared locally. Our supply chain strategy starts in New Brunswick first, then Canada, and only looks internationally when something can’t be sourced domestically. That approach creates opportunities for local businesses and skilled trades while respecting the role of Indigenous partners in the region’s energy future.

Nuclear energy still worries some people. How does ARC’s technology help address safety concerns?

From an industrial safety perspective, nuclear is among the safest forms of energy generation. Major accidents are extremely rare, and the risk from radiation is very low. The annual radiation dose from living near a nuclear power plant is a fraction of the radiation dose from a dental X-ray. The nuclear industry is highly regulated with oversight by experts and international agencies, making it extremely safe.

Building off some comments I made earlier,

Our reactor is “walk-away safe”, which means in any worst-case scenario, it will shut down and remove heat without operator action or powered equipment, and remain in a safe, stable condition indefinitely.